A hard disk drive (HDD) is a data storage device used for storing and retrieving digital information using rapidly rotating discs (platters) coated with magnetic material. An HDD retains its data even when powered off. Data is read in a random-access manner, meaning individual blocks of data can be stored or retrieved in any order rather than just sequentially. An HDD consists of one or more rigid ("hard") rapidly rotating discs (platters) with magnetic heads arranged on a moving actuator arm to read and write data to the surfaces.

Introduced by IBM in 1956, HDDs became the dominant secondary storage device for general purpose computers by the early 1960s. Continuously improved, HDDs have maintained this position into the modern era of servers and PCs. More than 200 companies have produced HDD units, though most current units are manufactured by Western Digital, Seagate, and Toshiba. Worldwide revenues for HDDs shipments are expected to reach $38 billion in 2012, up about 19% from $32 billion in 2011.

The primary characteristics of an HDD are its capacity and performance. Capacity is specified in unit prefixes corresponding to powers of 1000: a 1-terabyte (TB) drive has a capacity of 1,000 gigabytes (GB; where 1 gigabyte = 1 billion bytes). Typically, some of an HDD's capacity is unavailable to the user due to use by the file system and the computer operating system, and possibly inbuilt redundancy for error correction and recovery. Performance is specified by the time to move the heads to a file (average access time) plus the time it takes for the file to move under its head (average latency, a function of the physical rotational speed in revolutions per minute) and the speed at which the file is transmitted (data rate).

The two most common form factors for modern HDDs are 3.5-inch in desktop computers and 2.5-inch in laptops. Different sizes are used in specialty devices such as portable media players or in some server hardware. HDDs are connected to systems by standard interface cables such as SATA (Serial ATA), USB or SAS (Serial attached SCSI) cables.

As of 2012, the primary competing technology for secondary storage is flash memory in the form of solid-state drives (SSDs). HDDs are expected to remain the dominant medium for secondary storage for the forseeable future due to advantages in recording capacity and price per unit of storage, but solid state drives are replacing rotating hard drives especially in portable electronics where speed, physical size, and durability are more important considerations than price and capacity

Magnetic recording

See also: Magnetic storage

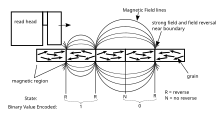

An HDD records data by magnetizing a thin film of ferromagnetic material on a disk. Sequential changes in the direction of magnetization represent binary data bits.

The data is read from the disk by detecting the transitions in

magnetization. User data is encoded using an encoding scheme, such as run-length limited encoding which determines how the data is represented by the magnetic transitions.A typical HDD design consists of a spindle that holds flat circular disks, also called platters, which hold the recorded data. The platters are made from a non-magnetic material, usually aluminium alloy, glass, or ceramic, and are coated with a shallow layer of magnetic material typically 10–20 nm in depth, with an outer layer of carbon for protection.For reference, a standard piece of copy paper is 0.07–0.18 millimetre (70,000–180,000 nm).

Information is written to and read from a platter as it rotates past devices called read-and-write heads that operate very close (often tens of nanometers) over the magnetic surface. The read-and-write head is used to detect and modify the magnetization of the material immediately under it. In modern drives there is one head for each magnetic platter surface on the spindle, mounted on a common arm. An actuator arm (or access arm) moves the heads on an arc (roughly radially) across the platters as they spin, allowing each head to access almost the entire surface of the platter as it spins. The arm is moved using a voice coil actuator or in some older designs a stepper motor.

In modern drives, the small size of the magnetic regions creates the danger that their magnetic state might be lost because of thermal effects. To counter this, the platters are coated with two parallel magnetic layers, separated by a 3-atom layer of the non-magnetic element ruthenium, and the two layers are magnetized in opposite orientation, thus reinforcing each other. Another technology used to overcome thermal effects to allow greater recording densities is perpendicular recording, first shipped in 2005, and as of 2007 the technology was used in many HDDs.

Components

The actuator is a permanent magnet and moving coil motor that swings the heads to the desired position. A metal plate supports a squat neodymium-iron-boron (NIB) high-flux magnet. Beneath this plate is the moving coil, often referred to as the voice coil by analogy to the coil in loudspeakers, which is attached to the actuator hub, and beneath that is a second NIB magnet, mounted on the bottom plate of the motor (some drives only have one magnet).

The voice coil itself is shaped rather like an arrowhead, and made of doubly coated copper magnet wire. The inner layer is insulation, and the outer is thermoplastic, which bonds the coil together after it is wound on a form, making it self-supporting. The portions of the coil along the two sides of the arrowhead (which point to the actuator bearing center) interact with the magnetic field, developing a tangential force that rotates the actuator. Current flowing radially outward along one side of the arrowhead and radially inward on the other produces the tangential force. If the magnetic field were uniform, each side would generate opposing forces that would cancel each other out. Therefore the surface of the magnet is half N pole, half S pole, with the radial dividing line in the middle, causing the two sides of the coil to see opposite magnetic fields and produce forces that add instead of canceling. Currents along the top and bottom of the coil produce radial forces that do not rotate the head.

The HDD's electronics control the movement of the actuator and the rotation of the disk, and perform reads and writes on demand from the disk controller. Feedback of the drive electronics is accomplished by means of special segments of the disk dedicated to servo feedback. These are either complete concentric circles (in the case of dedicated servo technology), or segments interspersed with real data (in the case of embedded servo technology). The servo feedback optimizes the signal to noise ratio of the GMR sensors by adjusting the voice-coil of the actuated arm. The spinning of the disk also uses a servo motor. Modern disk firmware is capable of scheduling reads and writes efficiently on the platter surfaces and remapping sectors of the media which have failed.

0 comments:

Post a Comment